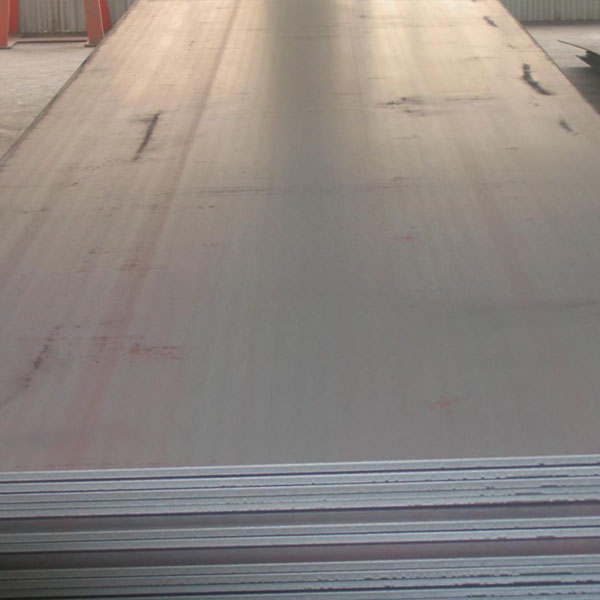

Siab Vessel Boiler Steel Phaj

(1) Cov ntsiab lus: Ntxiv rau qhov xav tau qee lub zog thiab tawv, cov khoom siv kuj tseem yuav tsum tau ua kom zoo ib yam, thiab cov teeb meem tsis zoo raug txwv nruj.

(2) Hom: Raws li kev faib tawm, nws tuaj yeem muab faib ua ob pawg: carbon steel phaj thiab alloy steel phaj; Raws li kev faib tawm lub zog, nws tuaj yeem muab faib ua siab, nruab nrab thiab qis siab steel phaj; Raws li kev siv ib puag ncig, nws tuaj yeem muab faib ua siab, nruab nrab thiab qis steel phaj thiab resistant steel daim hlau. Corrosion ntawm steel phaj.

(3) Cov chaw tsim khoom tseem ceeb thiab cov teb chaws tsim khoom tseem ceeb:

①Main domestic ntau lawm nroj tsuag: Wugang, Anshan hlau thiab hlau, Laiwu hlau, Shanghai hlau thiab hlau, Baotou hlau, Sangang, thiab lwm yam .;

②Tej lub teb chaws thiab cheeb tsam xa tawm txawv teb chaws: Nyiv, Russia, Lub teb chaws Yelemees, Eastern Europe thiab lwm lub teb chaws thiab cheeb tsam.

| Boiler phaj, thawv phaj xam qhov hnyav thickness | ||||

| Nominal thickness | Thickness ntxiv tus nqi | |||

| ≤1500 | > 1500-2500 | > 2500-4000 | > 4000-4800 | |

| 3.00-5.00 Nws | 0.25 | 0.35 Nws | ---- | |

| 6.00-8.00 Nws | 0.3 | 0.45 ib | ---- | |

| 9.00-15.00 Nws | 0.35 Nws | 0.5 | 0.6 | |

| 16.0-25.0 Nws | 0.45 ib | 0.6 | 0.8 ua | |

| 26.0-40.0 Nws | 0.5 | 0.7 ua | 0.9 | |

| 41-60.0 Nws | 0.6 | 0.8 ua | 1 | |

| 61.0 ~ 100 | 0.75 ib | 1 | 1.2 | |

| 101-150 : kuv | 1.1 | 1.3 | 1.5 | |

| 151-200 : kuv | 1.3 | 1.5 | 1.6 | |

| 201-250 : kuv | 1.5 | 1.7 | 1.9 | |

| 251-300 : kuv | 1.7 | 1.9 | 2.1 | |

| 301-400 Nws | 1.9 | 2.1 | 2.3 |

Lub thickness ntawm lub phaj siab phaj feem ntau yog li ntawm 5mm mus rau 200mm, thiab muab faib ua ob peb thickness specifications thaum lub sij hawm lub sij hawm. Lub teb chaws cov qauv teev cov ntawv qhia qhov ntau thiab tsawg thiab qhov sib txawv uas tso cai. Cov tsos zoo

(1) Cov duab ntawm steel phaj: xws li khoov khoov, flatness, txoj cai kaum, thiab lwm yam.

(2) Deg tsis xws luag: Cov defects ntawm lub phaj steel feem ntau muaj xws li cov kab nrib pleb, nti, flattened npuas, impurities, pob, pores, nias hlau oxide nplai, thiab lwm yam. Vim kev nyab xeeb yuav tsum tau, siab hlab ntsha steel daim hlau yuav tsum nruj me ntsis rau saum npoo thiab kev puas tsuaj sab hauv. Feem ntau, cov teeb meem saum toj no tsis raug tso cai kom muaj. Txawm li cas los xij, cov txheej txheem raug tso cai raug tshem tawm, thiab qhov chaw tshem tawm yuav tsum tiaj tus. Nws thickness yuav tsum tsis txhob ntau tshaj qhov tso cai sib txawv nyob rau hauv lub thickness ntawm steel phaj. Feem ntau, tsis pub interlayer. Chemical composition index:

① Carbon steel phaj: feem ntau pom cov ntsiab lus ntawm carbon, silicon, manganese, phosphorus, thiab sulfur. Qee cov pa roj carbon steel kuj muaj qee qhov tooj liab, chromium, nickel, molybdenum, vanadium thiab lwm yam khoom. Ntawm lawv, cov pa roj carbon monoxide yog qhov tseem ceeb los txiav txim siab lub zog ntawm cov phaj steel, uas yog, lub zog ntawm cov phaj steel nce nrog qhov nce ntawm cov ntsiab lus carbon. Cov ntsiab lus ntawm cov pa roj carbon steel yog nruab nrab ntawm 0.16 thiab 0.33%. Manganese thiab silicon kuj muaj cov txiaj ntsig ntawm kev txhim kho cov khoom siv thiab ua kom muaj zog. Silicon: 0.10 ~ 0.55%, manganese: 0.4 ~ 1.6%. Qee cov qauv tsis muaj cov kev cai ntawm silicon thiab manganese rau cov phaj boiler zoo tib yam, thiab tooj liab tsawg dua 0.30%. Lwm cov qauv xws li Nyiv thiab Russia tsis muaj cov ntsiab lus tooj liab. Qee cov hlau zoo muaj chromium (tsawg dua 0.25%), npib tsib xee (tsawg dua 0.30%), molybdenum (tsawg dua 0.10%), thiab vanadium (tsawg dua 0.03%). Cov tshuaj muaj pes tsawg leeg ntawm txhua qib ntawm boiler steel phaj yog qhia nyob rau hauv cov qauv khoom uas muaj nyob rau hauv Table 6-7-3.

Feem ntau liab qab los yog bundled. Rau cov kev cai ntawm smoothness thiab stainless hlau daim hlau, lub thawv los yog stows los yog brackets yuav tsum tau siv, thiab lawv yuav tsum tau qhwv nrog noo-pov thawj daim ntawv los yog lwm yam ntaub ntawv.

Laser tailor-welded dawb paug thiab tsis tu ncua sib txawv ntawm cross-section board technology

1. Tailor Welded Blanks (Tailor Welded Blanks, TWB) siv laser ua lub vuam kub los ua ke thiab vuam ntau yam khoom sib txawv, txawv thicknesses, thiab sib txawv coatings ntawm hlau, stainless hlau, aluminium alloy, thiab lwm yam rau hauv ib lub phaj tag nrho.

2. Siv laser tailored welding tshuab, nws yog ib qho tsim nyog los muab cov ntaub ntawv sib txawv thickness ntau thiab tsawg zog raws li cov kev ntxhov siab ntawm cov txheej txheem, txhim kho cov txheej txheem rigidity thaum txo qhov hnyav ntawm qhov chaw, thiab kuj nce kev siv tus nqi. ntawm cov ntaub ntawv thiab txo tus naj npawb ntawm qhov chaw. Tus naj npawb ntawm qhov chaw hauv cov txheej txheem simplifies. Laser txiav vuam tshuab tau dhau los ua cov txheej txheem tseem ceeb ntawm lub tsheb sib tw, thiab nws tau siv rau cov qauv ntawm ntau lub tuam txhab. Feem ntau siv nyob rau hauv pem hauv ntej thiab nram qab lub qhov rooj sab hauv panels, pem hauv ntej thiab nram qab longitudinal kab teeb, sab panels, pem teb panels, A, B, thiab C ncej nyob rau hauv lub qhov rooj, log npog thiab lub cev sab hauv panels, thiab lwm yam.

3. Tailor Rolling Blanks (TRB), tseem hu ua qhov sib txawv thickness daim hlau, hais txog lub sijhawm hloov pauv ntawm cov yob sib txawv ntawm lub computer thaum lub sij hawm dov txheej txheem ntawm cov hlau phaj, kom cov dov nyias phaj muaj kev txiav txim siab ua ntej. kev taw qhia raws txoj kev dov. Custom variable cross-sectional shape.

4. Kev hloov pauv tsis tu ncua ntawm cov khoom siv hluav taws xob sib txuas tau siv dav hauv kev tsim cov khoom siv lub cev, xws li lub cav npog, B-pillar, lub cev chassis, lub cev muaj zog qhia, nruab nrab kem sab hauv vaj huam sib luag, av nkos thiab lub thawv sib tsoo, thiab lwm yam. thiab tau ua tiav rau Audi, BMW, Volkswagen, GM thiab lwm yam qauv.

5. Laser tailored welding thiab nruam hloov pauv tsis tu ncua hla ntu thev naus laus zis hloov lub thickness ntawm cov khoom siv stamping los ntawm kev siv thev naus laus zis sib txawv, thiab siv los daws qhov teeb meem ntawm qhov sib txawv load-bearing muaj peev xwm yuav tsum tau rau qhov sib txawv ntawm nws pib qhov chaw nyob rau hauv load. Piv nrog rau ob, qhov zoo dua ntawm kev txiav laser vuam tshuab yog nyob rau hauv nws yooj yim, uas tuaj yeem paub qhov sib txuas ntawm txhua txoj haujlwm thiab kev sib txuas ntawm cov khoom sib txawv. Qhov kom zoo dua ntawm kev hloov pauv tsis tu ncua kev siv thev naus laus zis yog qhov tsis muaj vuam seam, kev hloov pauv ntawm qhov ntev ntawm qhov kev taw qhia yog maj mam, nws muaj kev tsim tau zoo dua, thiab qhov zoo ntawm qhov saum npoo yog qhov zoo, kev ua haujlwm zoo yog siab, thiab tus nqi yog. qis. Hnab, khoom siv kho mob, maus taus plhaub; tsheb, tsheb npav sab hauv lub ru tsev, dashboard; rooj zaum nraub qaum, vaj huam sib luag qhov rooj, qhov rais ncej, thiab lwm yam.