Laser Tailor-Welded Boiler Phaj

Kev thauj mus los: Txhawb kev thauj mus los hauv hiav txwv

Txuj: AiSi, ASTM, JIS

Qib: Ar360 400 450 NM400 450 500

Qhov chaw ntawm Keeb Kwm: Shandong, Suav

Qauv: Ar360 400 450 NM400 450 500

Hom: steel phaj, steel phaj

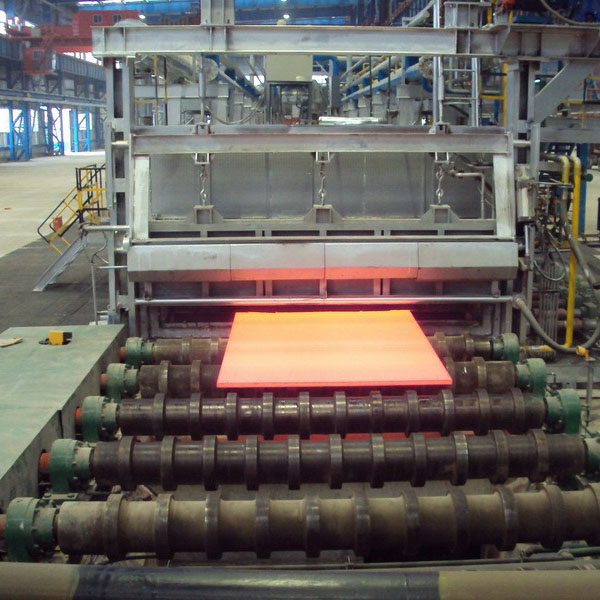

Txheej txheem: Kub dov

Kev kho deg: txheej

Daim ntawv thov: boiler phaj

Dav: 2000mm los yog raws li xav tau

Ntev: 5800mm 6000mm 8000mm

Kev kam rau siab: ± 5%

Cov kev pabcuam ua haujlwm: dabtsi yog khoov, vuam, uncoiling, txiav, xuas nrig ntaus

Khoom npe: Hnav-resistant steel phaj

Khoom siv: NM450 500 550 640 NM4400 450 500

Thickness: 3mm-100mm los yog raws li xav tau

Ntim: Standard airworthy ntim

Siv: Industrial

Shape: duab plaub

Muaj peev xwm muab khoom: 2000 tons / ton ib hlis

Packing cov ntsiab lus: advanced airworthy packing, kuj raws li tus neeg yuav tsum tau muaj.

Chaw nres nkoj: Qingdao, Tianjin, Shanghai

Kev txhim kho ntawm 20g hauv Jinan Hlau thiab Steel Group Corporation (lub npe hu ua Jigang) tau ua tiav ntau tshaj kaum xyoo dhau los, tab sis txwv rau qib ntawm cov txheej txheem thiab cov khoom siv thaum lub sijhawm ntawd, kev ua haujlwm ntawm steel phaj tsis ruaj khov, thiab muaj feem ntau muaj teeb meem ntawm qhov tsis sib xws ntawm qhov txias txias thiab kev laus zog.Cov kev ntsuas hauv qab no yuav tsum tau ua txhawm rau txhim kho qhov txias txias thiab kev laus zog thiab ua kom ntseeg tau tias qhov kub thiab txias cuam tshuam toughness:

(1) Kho cov khoom tswj sab hauv thiab ua kom qis qis ntawm manganese cov ntsiab lus rau 0.65%.

(2) Kev ua haujlwm zoo ntawm "Trinity" ntawm cov xaim pub mis, kev tswj qhov kub thiab txias tau txais yuav.

(3) nruj me ntsis tswj lub pouring kub.

(4) Cov ntsiab lus ntawm microalloyed keeb Ti tau nce los ntawm 0.003% mus rau ntau tshaj 0.008%.(5) Tag nrho cov txheej txheem tiv thaiv pouring txheej txheem yog saws los txo qhov nqus ntawm n

Cov txheej txheem ntau lawm:20g (Ti) boiler phaj yog ib hom hlau uas yuav tsum muaj siab rau cov khoom siv dav dav, cov hlau ntshiab, thiab cov khoom sib xyaw ua ke thiab cov khoom siv microalloying uas muaj kev cuam tshuam ntau dua rau cov teebmeem ntawm ntau yam khoom.Yog li, tus yuam sij rau 20g (Ti) cov txheej txheem tsim khoom yog txhawm rau txhim kho cov txheej txheem melting, txo tag nrho cov nqi ntawm cov khoom siv hauv cov hlau, xaiv cov khoom tsim nyog microalloying, siv cov kev tswj dov, txhim kho cov phaj zoo, thiab ruaj khov ntawm daim ntawv thov. kev laus cuam tshuam.Txoj kev ntawm 20g yog: zoo molten hlau → purification kho → smelting ntawm muaj pes tsawg leeg optimization thiab steel purification → microalloying thiab refining ntawm molten steel → tiv thaiv casting → zoo slab → tswj cua sov → kub tswj dov → phaj puab thiab thickness tswj → Tswj cua txias → khoom.

Laser tailor-welded dawb paug thiab tsis tu ncua sib txawv ntawm cross-section board technology

1. Tailor Welded Blanks (Tailor Welded Blanks, TWB) siv laser ua lub vuam kub los ua ke thiab vuam ntau yam khoom sib txawv, txawv thicknesses, thiab sib txawv coatings ntawm hlau, stainless hlau, aluminium alloy, thiab lwm yam rau hauv ib lub phaj tag nrho.

2. Siv laser tailored welding tshuab, nws yog ib qho tsim nyog los muab cov ntaub ntawv sib txawv thickness ntau thiab tsawg zog raws li cov kev ntxhov siab ntawm cov txheej txheem, txhim kho cov txheej txheem rigidity thaum txo qhov hnyav ntawm qhov chaw, thiab kuj nce kev siv tus nqi. ntawm cov ntaub ntawv thiab txo tus naj npawb ntawm qhov chaw.Tus naj npawb ntawm qhov chaw hauv cov txheej txheem simplifies.Laser txiav vuam tshuab tau dhau los ua cov txheej txheem tseem ceeb ntawm lub tsheb sib tw, thiab nws tau siv rau cov qauv ntawm ntau lub tuam txhab.Feem ntau siv nyob rau hauv pem hauv ntej thiab nram qab lub qhov rooj sab hauv panels, pem hauv ntej thiab nram qab longitudinal kab teeb, sab panels, pem teb panels, A, B, thiab C ncej nyob rau hauv lub qhov rooj, log npog thiab lub cev sab hauv panels, thiab lwm yam.

3. Tailor Rolling Blanks (TRB), tseem hu ua qhov sib txawv thickness daim hlau, hais txog lub sijhawm hloov pauv ntawm cov yob sib txawv ntawm lub computer thaum lub sij hawm dov txheej txheem ntawm cov hlau phaj, kom cov dov nyias phaj muaj kev txiav txim siab ua ntej. kev taw qhia raws txoj kev dov.Custom variable cross-sectional shape.

4. Kev hloov pauv tsis tu ncua ntawm cov khoom siv hluav taws xob sib txuas tau siv dav hauv kev tsim cov khoom siv lub cev, xws li lub cav npog, B-pillar, lub cev chassis, lub cev muaj zog qhia, nruab nrab kem sab hauv vaj huam sib luag, av nkos thiab lub thawv sib tsoo, thiab lwm yam. thiab tau ua tiav rau Audi, BMW, Volkswagen, GM thiab lwm yam qauv.

5. Laser tailored welding thiab nruam hloov pauv tsis tu ncua hla ntu thev naus laus zis hloov lub thickness ntawm cov khoom siv stamping los ntawm kev siv thev naus laus zis sib txawv, thiab siv los daws qhov teeb meem ntawm qhov sib txawv load-bearing muaj peev xwm yuav tsum tau rau qhov sib txawv ntawm nws pib qhov chaw nyob rau hauv load.Piv nrog rau ob, qhov zoo dua ntawm kev txiav laser vuam tshuab yog nyob rau hauv nws yooj yim, uas tuaj yeem paub qhov sib txuas ntawm txhua txoj haujlwm thiab kev sib txuas ntawm cov khoom sib txawv.Qhov kom zoo dua ntawm kev hloov pauv tsis tu ncua kev siv thev naus laus zis yog qhov tsis muaj vuam seam, kev hloov pauv ntawm qhov ntev ntawm qhov kev taw qhia yog maj mam, nws muaj kev tsim tau zoo dua, thiab qhov zoo ntawm qhov saum npoo yog qhov zoo, kev ua haujlwm zoo yog siab, thiab tus nqi yog. qis.Hnab, khoom siv kho mob, maus taus plhaub;tsheb, tsheb npav sab hauv lub ru tsev, dashboard;rooj zaum nraub qaum, vaj huam sib luag qhov rooj, qhov rais ncej, thiab lwm yam.

| A516 Gr.60 | A516 Gr.65 | A516 Gr.70 | |

| Tensile zog (Ksi) | 60-80 | 65-85 : kuv | 70-90 : kuv |

| Tensile zog (Mpa) | 415-550 : kuv | 450-585 : kuv | 485-620 : kuv |

| Yield zog (Ksi) | 32 | 35 | 38 |

| Yield zog (Mpa) | 220 | 240 | 260 |

| 200mm Elongation (%) | 21 | 19 | 17 |

| 50mm Elongation (%) | 25 | 23 | 21 |

| Qhov siab tshaj plaws Thickness (Mm) | 205 | 205 | 205 |