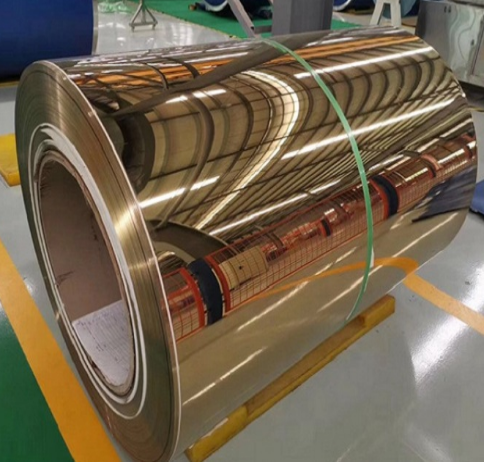

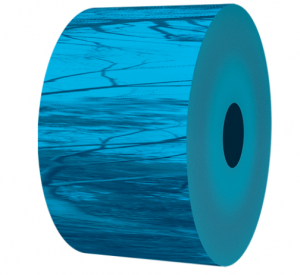

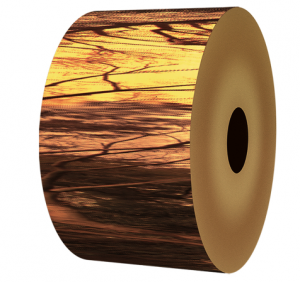

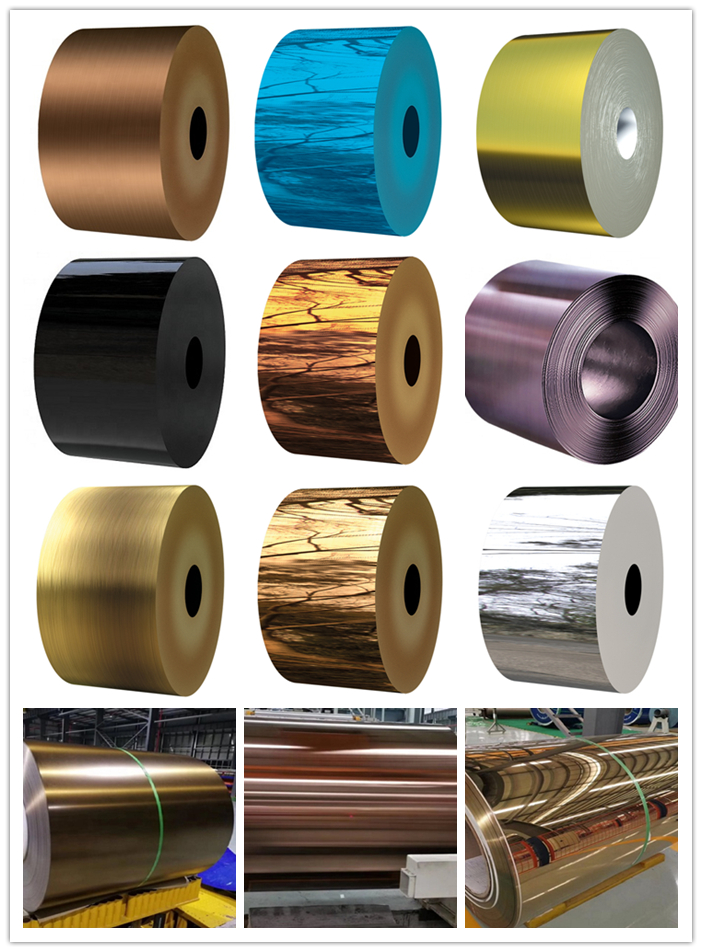

8K Daim iav Xim SS201,304,430,316 Stainless Hlau Chev

| Chemical Composition thiab Mechanical Properties of XimStainless Hlau Coils | |||||||||

| Qib | Chemical Composition (%) | Mechanieal Kev Ua Haujlwm | |||||||

|

| C | Si | Mn | P | S | Ni | Cr | Mo | Hardness |

| 201 | ≤ 0.15 | ≤ 1.00 | 5.5 / 7.5 | ≤ 0.060 | ≤ 0.030 | 3.5 / 5.5 | 16.0/18.0 Nws | - | HB≤241, HRB≤100, HV≤240 |

| 304 | ≤ 0.08 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.03 | 8.0/11.0 Nws | 18.00/20.00 Nws | - | HB≤187, HRB≤90, HV≤200 |

| 316 | ≤ 0.08 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.03 | 10.00/14.00 Nws | 16.0/18.0 Nws | 2.00 / 3.00 Nws | HB≤187, HRB≤90, HV≤200 |

| 316l ua | ≤ 0.03 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.03 | 10.00/14.00 Nws | 16.0/18.0 Nws | 2.00 / 3.00 Nws | HB≤187, HRB≤90, HV≤200 |

| 410 | ≤ 0.15 | ≤ 1.00 | ≤1.25 | ≤ 0.060 | ≤ 0.030 | ≤ 0.060 | 11.5/13.5 Nws | - | HB≤183, HRB≤88, HV≤200 |

| 430 | ≤ 0.12 | ≤ 1.00 | ≤1.25 | ≤ 0.040 | ≤ 0.03 | - | 16.00/18.00 Nws | - | HB≤183, HRB≤88, HV≤200 |

1. Kev ua haujlwm tshaj lij.

2.OEM & ODM, kuj muab kev pabcuam customized.

3.Kev muab rau koj tus qauv tsim tshwj xeeb thiab qee qhov peb cov qauv tam sim no.

4.Kev tiv thaiv ntawm koj thaj chaw muag khoom, cov tswv yim ntawm kev tsim thiab tag nrho koj cov ntaub ntawv ntiag tug.

5.Muaj kev kuaj xyuas nruj rau txhua ntu, txhua txheej txheem ua ntej xa tawm.

6.Muaj kev pabcuam tomqab muag tag, suav nrog kev teeb tsa, kev qhia.

1. Txiav kom ntev

2.Despoiling thiab slitting

3. Sib tsoo thiab txhuam

4. Zaj duab xis tiv thaiv

5.Plasma thiab dej dav hlau txiav

6. Embossing

7. Daim iav los yog lwm yam tiav