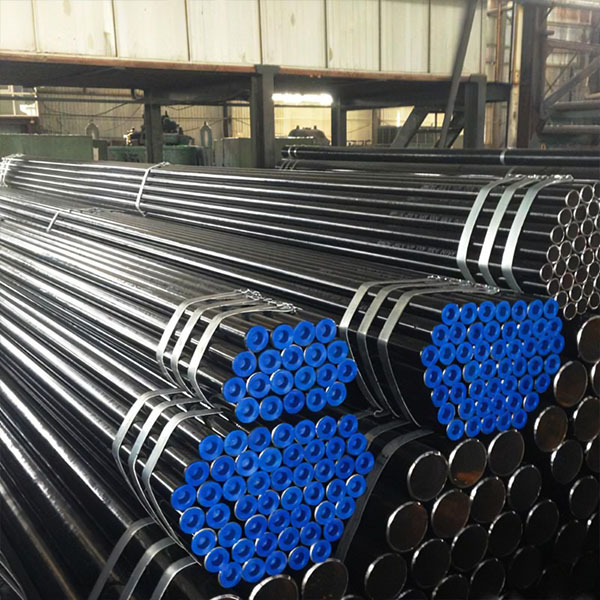

P91 Khoom Alloy Tube

P91 alloy yeeb nkab raws li GB / T8162-87

4.1. Specifications: Sab nraud txoj kab uas hla ntawm lub raj kub dov yog 32 ~ 630mm. Phab ntsa thickness yog 2.5 ~ 75mm. Sab nraud txoj kab uas hla ntawm txias dov (txias kos) yeeb nkab yog 5 ~ 200mm. Phab ntsa thickness yog 2.5-12mm.

4.2. Cov tsos mob zoo: sab hauv thiab sab nrauv ntawm cov yeeb nkab steel yuav tsum tsis txhob muaj cov kab nrib pleb, folds, yob, delamination, kab plaub hau thiab caws pliav. Cov kev tsis zoo no yuav tsum raug tshem tawm tag nrho, thiab cov phab ntsa tuab thiab sab nraud yuav tsum tsis txhob dhau qhov tsis zoo sib txawv tom qab tshem tawm.

Txoj kev tsim khoom

Raws li cov txheej txheem ntau lawm, nws tuaj yeem muab faib ua cov raj kub dov, cov raj txias dov, cov raj txias txias, cov raj extruded, thiab lwm yam.

1.1. Kub dov P91 alloy raj feem ntau yog tsim los ntawm tsis siv neeg raj dov mills. Cov khoom siv lub raj raug tshuaj xyuas thiab ntxuav ntawm qhov chaw tsis xws luag, txiav mus rau qhov ntev uas yuav tsum tau ua, nyob rau hauv lub perforated kawg ntawm lub raj, thiab ces xa mus rau lub cua sov rauv kom sov thiab pierced ntawm lub tshuab tho. Thaum lub perforation tsis tu ncua rotates thiab nce nyob rau tib lub sij hawm, nyob rau hauv qhov kev txiav txim ntawm cov menyuam thiab lub ntsaws, ib kab noj hniav yog maj mam tsim nyob rau hauv lub raj dawb paug, uas yog hu ua ib tug capillary raj. Thiab ces xa mus rau qhov tsis siv neeg dov zeb mus txuas ntxiv dov. Thaum kawg, tag nrho cov phab ntsa tuab yog uniformed los ntawm lub tshuab sib npaug, thiab txoj kab uas hla yog sizing los ntawm lub tshuab sizing kom tau raws li qhov yuav tsum tau ua. Nws yog ib txoj hauv kev zoo tshaj los tsim cov kub dov P91 alloy kav uas siv cov yeeb nkab txuas txuas ntxiv.

1.2. Yog tias koj xav tau cov kav dej seamless nrog me me thiab zoo dua, txias dov, kos duab txias, lossis kev sib xyaw ntawm ob txoj kev yuav tsum tau siv. Txias dov feem ntau yog ua los ntawm ob-siab dov zeb. Cov yeeb nkab steel yog dov nyob rau hauv ib qho annular pass tsim los ntawm qhov sib txawv ntawm qhov sib txawv ntawm qhov sib txuas qhov zawj thiab ib lub ntsaws ntsaws ruaj ruaj. Kev kos duab txias feem ntau yog ua los ntawm ib leeg-chain lossis ob-chain txias tshuab kos duab ntawm 0.5 txog 100T.

1.3. Txoj kev extrusion yog muab tso rau hauv lub qhov cub kub kub hauv lub tog raj kheej kaw, thiab tus pas nrig perforated thiab tus pas nrig extrusion txav mus ua ke kom extruded qhov extruded los ntawm qhov me me tuag qhov. Txoj kev no tuaj yeem tsim cov kav hlau nrog cov kab me me.

2.1. P91 alloy raj muaj ntau yam kev siv. Lub hom phiaj dav dav P91 alloy yeeb nkab yog dov los ntawm cov pa roj carbon zoo tib yam steel, qis-alloy structural steel lossis alloy structural steel, thiab muaj cov khoom loj tshaj plaws. Nws yog tsuas yog siv los ua cov kav dej lossis cov khoom siv rau kev xa cov kua dej.

2.2. Raws li lub hom phiaj sib txawv, nws muab faib ua peb hom khoom: a. Raws li tshuaj muaj pes tsawg leeg thiab txhua yam khoom; b. Raws li mechanical zog; c. Raws li kev ntsuas hydraulic. Cov kav hlau xa khoom raws li pawg a thiab b, yog tias siv los tiv thaiv cov kua siab, yuav tsum raug kuaj xyuas hydraulic.

2.3. P91 alloy kav rau lub hom phiaj tshwj xeeb suav nrog P91 alloy kav rau boilers, P91 alloy kav rau geology thiab seamless kav rau roj av.

Lub ntsiab alloying ntsiab ntawm cov kav hlau yog silicon, manganese, chromium, npib tsib xee, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, txhuas, tooj liab, boron, tsis tshua muaj ntiaj teb, thiab lwm yam.Alloy steel kav muaj hlau, carbon thiab ib tug me me ntawm indispensable Ntxiv nrog rau kev zam silicon, manganese, phosphorus, thiab sulfur, nws kuj muaj ib tug npaum li cas ntawm alloying ntsiab.Cov alloying ntsiab nyob rau hauv steel muaj xws li silicon, manganese, molybdenum, npib tsib xee, sulphur, vanadium, titanium, niobium, boron, lead, tsis tshua muaj ntiaj teb, thiab lwm yam. Ib los yog ntau hom hlau yog hu ua alloy steels. Lub tshuab hlau alloy sib txawv nrog lawv cov peev txheej, kev tsim khoom thiab kev siv. Yav dhau los, nickel thiab steel systems tau tsim nyob rau hauv txawv teb chaws. Tuam Tshoj tau pom tias silicon, manganese, Vanadium, titanium, niobium, boron, lead, thiab tsis tshua muaj ntiaj teb alloy steel system alloy steel nyiaj li ntawm kaum feem pua ntawm tag nrho cov khoom siv hlau. Feem ntau, cov yeeb nkab steel hlau tuaj yeem muab faib ua 8 hom loj raws li lawv siv. Hom, lawv yog: alloy structural steel kav, caij nplooj ntoos hlav steel kav, bearing steel kav, alloy cuab tam steel kav, high-speed tool steel kav, stainless hlau kav, tshav kub-resistant non-skinned steel kav, hluav taws xob silicon steel kav PC/ABS muaj cov formability zoo thiab tuaj yeem ua tiav rau cov tsheb loj Cheebtsam, xws li tsheb fenders, muaj tus nqi siab. Alloy steel kav yog tsim los ntawm cov pa roj carbon zoo tib yam los ntawm kev ntxiv qhov tsim nyog ntawm ib lossis ntau lub ntsiab lus alloying rau kev faib cov hlau-carbon alloy steel kav: steel kav muab faib ua P91 alloy kav thiab vuam steel kav thiab lwm yam.