Ordinary Flat Steel

Tshooj hlau yog ib qho ntawm plaub hom hlau loj (phaj, raj, profile, hlau). Raws li cov duab seem, seem hlau tau muab faib ua ntu ntu steel thiab ntu ntu steel (section steel). Lub qub yog hais txog square steel, round steel, ca steel, kaum steel, hexagonal steel, thiab lwm yam .; tom kawg yog hais txog I-beam, channel steel, steel rail, qhov rai ncej steel, nkhaus steel, thiab lwm yam.

Galvanized tiaj tus hlau tuaj yeem siv los ua cov hlau hoop, cov cuab yeej thiab cov khoom siv kho tshuab ua cov khoom tiav, thiab siv los ua cov qauv hauv tsev thiab cov escalators hauv kev tsim kho.

Galvanizing txheej txheem

Kub-dip galvanizing tseem hu ua kub-dip galvanizing thiab kub-dip galvanizing: nws yog ib txoj kev zoo hlau los tiv thaiv corrosion, feem ntau yog siv hauv cov qauv hlau hauv ntau qhov kev lag luam. Cov hlau uas tshem tawm xeb tau muab tso rau hauv cov tshuaj zinc molten ntawm li 500 ° C, kom cov zinc txheej txuas rau saum npoo ntawm cov hlau, yog li ua tiav lub hom phiaj ntawm kev tiv thaiv corrosion.

Kub-dip galvanizing txheej txheem: tiav cov khoom pickling-dej ntxuav-ntxiv auxiliary plating tov-drying-rack plating-txias-tshuaj-tshuaj-polishing-kub-dip galvanizing tiav

Kub-dip galvanizing yog tsim los ntawm txoj kev kub-dip qub. Nws muaj keeb kwm ntawm 140 xyoo txij li thaum Fabkis tau siv kub-dip galvanizing rau kev lag luam hauv xyoo 1836. Txawm li cas los xij, kev lag luam kub-dip galvanizing tau tsim los ntawm cov nplai loj nrog txoj kev loj hlob sai ntawm cov khaub thuas dov strip steel hauv 30 xyoo dhau los.

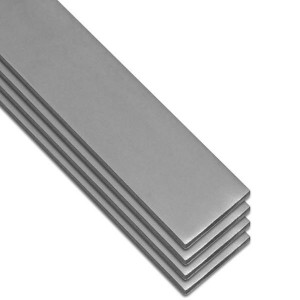

1. Cov khoom specifications yog tshwj xeeb. Lub thickness yog 8-50mm, qhov dav yog 150-625mm, qhov ntev yog 5-15m, thiab cov khoom specifications kuj ntom, uas yuav ua tau raws li cov kev xav tau ntawm cov neeg siv. Nws tuaj yeem siv los hloov cov phaj nruab nrab thiab tuaj yeem ncaj qha welded yam tsis muaj kev txiav.

2. Qhov saum npoo ntawm cov khoom yog du thiab huv. Cov txheej txheem dej siab descaling yog siv ob zaug hauv cov txheej txheem los xyuas kom meej cov hlau nto du thiab huv.

3. Ob sab yog ntsug thiab cov txiv ntseej dej ntshiab. Qhov thib ob ntsug dov nyob rau hauv lub tiav dov kom ntseeg tau zoo verticality ntawm ob sab, meej cov ces kaum, thiab zoo nto zoo ntawm ob sab.

4. Cov nplai ntawm cov khoom yog qhov tseeb, peb lub ntsiab lus sib txawv, tib theem sib txawv yog zoo dua li cov qauv steel phaj; cov khoom yog ncaj thiab cov phaj zoo zoo. Kev ua tiav dov siv cov txheej txheem txuas ntxiv mus, tsis siv neeg looper tsis siv neeg tswj, kom ntseeg tau tias tsis muaj steel piled los yog ncab, cov khoom seem qhov tseeb yog siab, qhov kam rau ua ntau yam, peb-taw tes sib txawv, tib kab sib txawv, khoov khoov thiab lwm yam tsis muaj. zoo tshaj qhov nruab nrab phaj, thiab lub phaj zoo yog ncaj. Qib kawm tau zoo. Txias shearing, siab precision ntawm qhov ntev sizing.

5. Cov khoom siv tau txais cov qauv hauv teb chaws, uas yog tib yam li cov hlau phaj. Cov qauv zoo thiab cov qauv tsim tau raug teeb tsa raws li YB / T4212-2010 tus qauv (Q345B / Q235B xa mus rau GB / T1591-94 thiab GB / T700-88 tus qauv raws li).

1. Lub zog muaj zog, lub teeb pom kev zoo: lub zog ruaj khov siab vuam qauv ua rau nws muaj cov yam ntxwv ntawm cov kabmob siab, lub teeb qauv thiab yooj yim hoisting;

2. Zoo nkauj tsos thiab kav ntev.

Precision ca steel ntau lawm txheej txheem Lub hauv paus ntsiab lus ntawm kev ua hauj lwm ntawm lub tiaj tiaj hlau xov tshuab yog siv ob txheej ntawm staggered nce thiab down leveling log mus rau qib ua ntej thiab theem kawg lub thickness kev taw qhia ntawm txias ca steel ntaub plaub; siv ib tug khub ntawm oppositely teem tiav Lub log yog nyem nyob rau hauv dav kev taw qhia kom lub dav yog compressed mus cuag cov kev cia siab tsis, thiab tus nqi compression yog adjustable; siv 5 staggered straightening log kom ncaj qhov dav. Cov txheej txheem no feem ntau yog tsim los ntawm lub thawv tswj, lub tshuab ua tiav, chav ua ntej-leveling, chav ua tiav, thiab chav ncaj.

Cov txheej txheem ntau lawm tuaj yeem raug suav hais tias yog: pre-leveling → tiav → straightening → post-leveling. Pav ca steel / a / b yog cov hlau uas muaj qhov dav ntawm 12-300mm, tuab ntawm 4-60mm, ib lub duab plaub ntu thiab cov npoo ntshiab me ntsis. Cov hlau tiaj tus tuaj yeem yog cov khoom siv hlau tiav, lossis nws tuaj yeem siv los ua ib qho khoom siv rau cov kav dej thiab cov slabs nyias rau cov ntawv txheeb. Daim ntawv thov tseem ceeb: Cov hlau tiaj tus tuaj yeem siv los ua cov hlau hoop, cov cuab yeej thiab cov khoom siv kho tshuab ua cov khoom tiav, thiab siv los ua lub tsev thav duab thiab escalator hauv kev tsim kho. Pav ca hlau tau muab faib ua ob hom raws li nws cov duab: lub caij nplooj ntoos hlav tiaj tus steel thiab ib leeg-ib tog ob groove caij nplooj ntoos hlav ca steel. Kub dov caij nplooj ntoos hlav ca hlau yog tsuas yog siv los tsim cov nplooj springs rau tsheb, tsheb laij teb, tsheb thauj mus los thiab lwm yam tshuab.

Txheej txheem txheej txheem ntawm caij nplooj ntoos hlav ca steel rau tsheb

Lub caij nplooj ntoos hlav ca steel yog tsim los ntawm converter smelting txheej txheem. Piv nrog rau cov cuab yeej technology uas twb muaj lawm, nws muaj qhov zoo hauv qab no thiab cov txiaj ntsig zoo:

1. Flat steel smelting nyob rau hauv ib tug converter mas siv molten hlau li raw khoom, uas muaj tsawg teeb meem ntsiab nyob rau hauv lub molten hlau, thiab qhov zoo ntawm lub tiaj tiaj steel yog guaranteed.

2. Vim tias cov khoom lag luam siab thiab kev siv hluav taws xob tsawg, tus nqi ib tuj qis dua li ntawm cov hluav taws xob rauv taws.

3. Lub molten steel yog ncaj qha nrum rau hauv billets, uas tshem tawm cov txheej txheem billeting thiab txo tus nqi.

4. Lub nruam casting billet muaj qhov siab txiav-rau-ntev tus nqi, uas tuaj yeem lav lub tiaj-steel txiav-rau-ntev tus nqi thiab ua tau raws li cov neeg siv khoom xav tau.