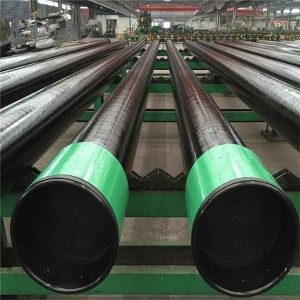

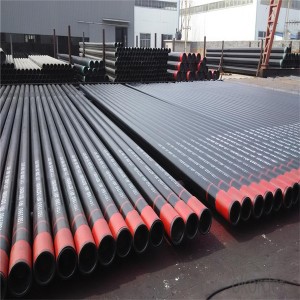

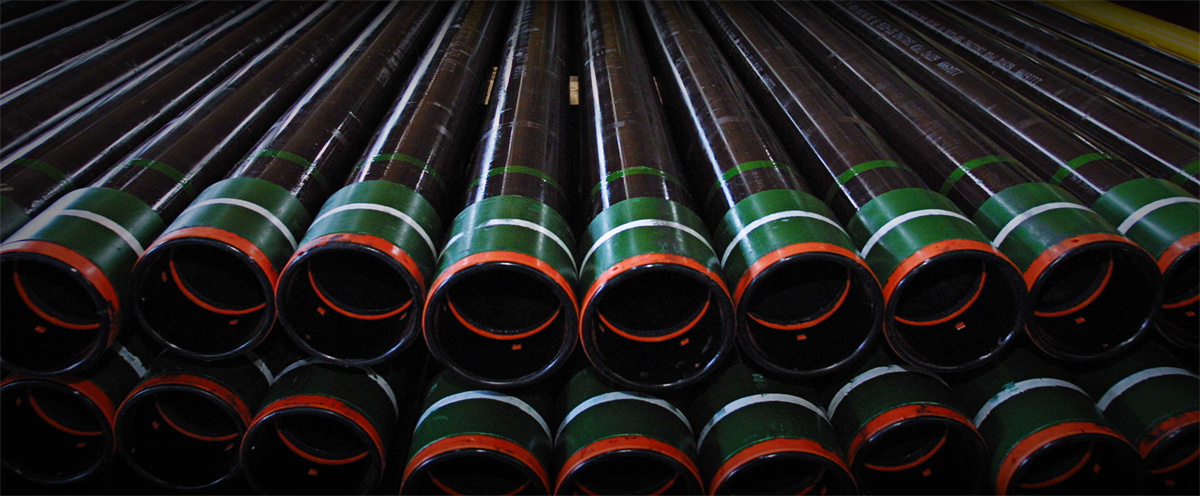

J55 K55 N80 Roj Tubing thiab Casing Hlau Yeeb

Roj casing yog cov yeeb nkab steel siv los txhawb cov phab ntsa ntawm cov roj thiab cov roj qhov dej kom ntseeg tau tias kev ua haujlwm zoo ntawm tag nrho cov roj zoo tom qab cov txheej txheem drilling thiab ua tiav. Txhua lub qhov dej siv ob peb txheej ntawm casing raws li qhov sib txawv drilling qhov tob thiab geological tej yam kev mob. Cement cementing yog siv tom qab lub casing txo qis rau hauv qhov dej. Tsis zoo li cov kav dej thiab cov kav dej tho, nws tsis tuaj yeem rov qab siv dua thiab yog cov khoom siv ib zaug. Yog li ntawd, kev siv cov casing tso nyiaj rau ntau tshaj 70% ntawm tag nrho cov kav dej.

| Daim ntawv lo | D Sab nraud txoj kab uas hla mm | Phab ntsa thickness t mm | C Hom kawg-finish | |||||||||

| 1 | 2 | |||||||||||

| NU T&C | EU T&C | IJ | ||||||||||

| H40 | J55 | l80 ua | n801 qw | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.9 | 2.75 ib | 2.9 | 2.76 ib | 48.26 Nws | 3.68 ib | PNUI | PNUI | PNUI | PNUI | PNUI | PNUI | - |

| 1.9 | 3.65 ib | 3.73 ib | - | 48.26 Nws | 5.08 Nws | PU | PU | PU | PU | PU | PU | PU |

| 1.9 | 4.42 ib | - | - | 48.26 Nws | 6.35 Nws | - | - | P | - | P | P | - |

| 2 3/8 | 4 | - | - | 60.32 Nws | 4.24 ib | PU | PN | PN | PN | PN | PN | - |

| 2 3/8 | 4.6 | 4.7 | - | 60.32 Nws | 4.83 ib | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 5.8 | 5.95 ib | - | 60.32 Nws | 6.45 Nws | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 6.6 | - | - | 60.32 Nws | 7.49 ib | - | - | P | - | P | P | - |

| 2 3/8 | 7.35 Nws | 7.45 Nws | - | 60.32 Nws | 8.53 ib | - | - | PU | - | PU | PU | - |

| 2 7/8 ib | 6.4 | 6.5 | - | 73.02 ib | 5.51 ib | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 ib | 7.8 ib | 7.9 ib | - | 73.02 ib | 7.01 Nws | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 ib | 8.6 | 8.7 ib | - | 73.02 ib | 7.82 ib | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 ib | 9.35 Nws | 9.45 Nws | - | 73.02 ib | 8.64 ib | - | - | PU | - | PU | PU | - |

| 2 7/8 ib | 10.5 | - | - | 73.02 ib | 9.96 ib | - | - | P | - | P | P | - |

| 3 1/2 | 7.7 | - | - | 88.9 ua | 5.49 ib | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 9.2 ib | 9.3 | - | 88.9 ua | 6.45 Nws | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 10.2 | - | - | 88.9 ua | 7.34 ib | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 12.7 ib | 12.95 Nws | - | 88.9 ua | 9.52 ib | - | - | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 14.3 | - | - | 88.9 ua | 10.92 Nws | - | - | P | - | P | P | - |

| 3 1/2 | 15.5 ib | - | - | 88.9 ua | 12.09 Nws | - | - | P | - | P | P | - |

| 4 | 9.5 ib | - | - | 101.6 ib | 5.74 ib | PN | PN | PN | PN | PN | PN | - |

| 4 | 10.7 ib | 11 | - | 101.6 ib | 6.65 ib | PU | PU | PU | PU | PU | PU | - |

| 4 | 13.2 | - | - | 101.6 ib | 8.38 ib | - | - | P | - | P | P | - |

| 4 | 16.1 | - | - | 101.6 ib | 10.54 Nws | - | - | P | - | P | P | - |

| 4 1/2 | 12.6 | 12.75 Nws | - | 114.3 ib | 6.88 ib | PNU | PNU | PNU | PNU | PNU | PNU | - |

| 4 1/2 | 15.2 | - | - | 114.3 ib | 8.56 ib | - | - | P | - | P | P | - |

| Pab pawg | Qib | Hom | Tag nrho elongation nyob rau hauv load% | Yield zog Mpa | Tensile zog min MPa | Hardness max | ||

| min | max | HRC | HBW | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 1 | J55 | - | 0.5 | 379 ib | 552 ib | 517 ib | - | - |

| k55 ua | - | 0.5 | 379 ib | 552 ib | 655 | - | - | |

| N80 | 1 | 0.5 | 552 ib | 758 ib | 689 ib | - | - | |

| N80 | Q | 0.5 | 552 ib | 758 ib | 689 ib | - | - | |

| 2 | l80 ua | 1 | 0.5 | 552 ib | 655 | 655 | 23 | 241 |

| l80 ua | 9 cr ua | 0.5 | 552 ib | 655 | 655 | 23 | 241 | |

| l80 ua | 13 Cr | 0.5 | 552 ib | 655 | 655 | 23 | 241 | |

| C90 | 1?2 | 0.5 | 621 ib | 724 ib | 689 ib | 25.4 ib | 255 | |

| C95 | - | 0.5 | 655 | 758 ib | 724 ib | - | - | |

| T95 | 1?2 | 0.5 | 655 | 758 ib | 724 ib | 25.4 ib | 255 | |

| 3 | P110 | - | 0.6 | 758 ib | 965 ib | 862 ib | - | - |

| 4 | q125 ua | Tag nrho | 0.65 ib | 862 ib | 1034 ib | 931 ib | - | - |

Visual tshuaj xyuas rau cov yeeb nkab nto

Dimension check

Mechanical test ntawm tensile lub zog, tawm los lub zog thiab elongation

Tshuaj ntsuam xyuas

NDT xeem suav nrog Magnetic particle, Ultrasonic Test, Hydrostatic Test

Charpy impact test

Flattening xeem

Kev kuaj Hardness

Drift test

Xov xaus check nrog xov gauge thiab coupling check

J55 thiab K55 yog cov khoom zoo sib xws hauv cov tshuaj muaj pes tsawg leeg thiab cov khoom siv kho tshuab, tshwj xeeb tshaj yog J55 muaj qhov tsawg kawg nkaus tensile yuav tsum tau thiab qis elongation, lwm yam specifications zoo ib yam li cov kev kho cua sov, NDE xeem, Charpy Impact test, hydrostatic test.

J55 / K55 yam tsawg kawg nkaus lub zog: 379-552 Mpa;

J55 yam tsawg kawg nkaus tensile zog: 517 Mpa, elongation ≥ 19%;

K55 yam tsawg kawg nkaus tensile zog: 655 Mpa, elongation ≥ 15%.