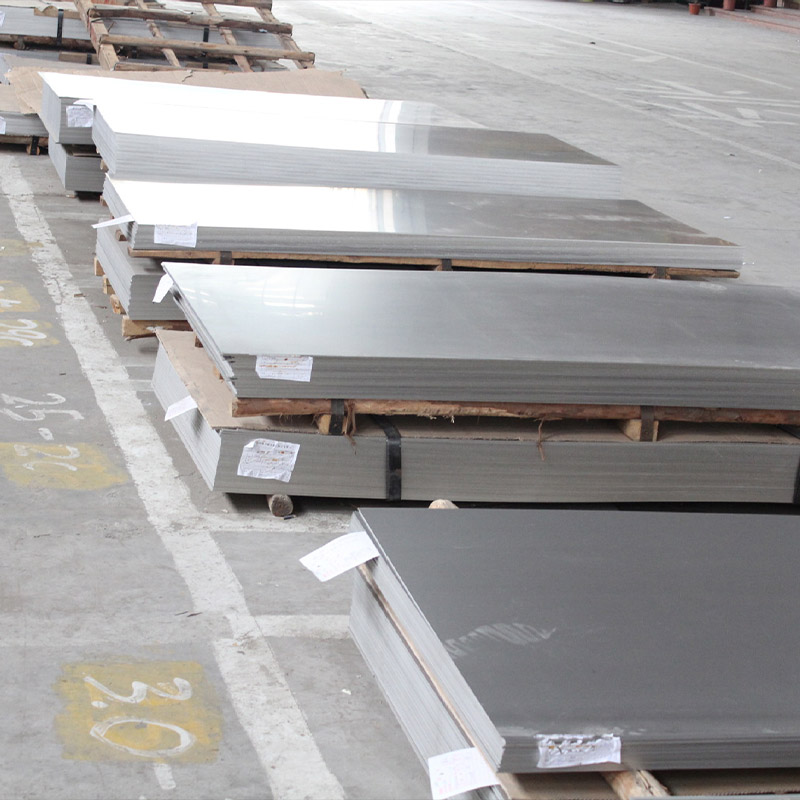

Kub Rolled Stainless Hlau Phaj

Nws yuav tsum muaj peev xwm tiv taus corrosion ntawm oxalic acid, sulfuric acid hlau sulfate, nitric acid, nitric acid hydrofluoric acid, sulfuric acid tooj liab sulfate, phosphoric acid, formic acid, acetic acid thiab lwm yam acids. Nws yog dav siv hauv kev lag luam chemical, zaub mov, tshuaj, papermaking, roj av, atomic zog thiab lwm yam kev lag luam, nrog rau ntau qhov chaw ntawm lub tsev, chav ua noj, tais diav, tsheb thiab khoom siv hauv tsev. Txhawm rau kom ntseeg tau tias cov khoom siv hluav taws xob xws li lub zog tawm los, lub zog tensile, elongation thiab hardness ntawm ntau yam stainless hlau daim hlau ua tau raws li qhov yuav tsum tau ua, cov hlau phaj yuav tsum tau txais kev kho cua sov xws li annealing, tshuaj kho thiab kev laus kho ua ntej xa khoom.

Stainless hlau phaj muaj du nto, siab plasticity, toughness thiab mechanical zog, thiab yog resistant rau corrosion ntawm acid, alkaline gas, tov thiab lwm yam xov xwm. Nws yog ib hom hlau alloy uas tsis yooj yim rau xeb, tab sis nws tsis yog xeb kiag li.

Kev tiv thaiv corrosion ntawm stainless hlau tsuas yog nyob ntawm nws cov alloy muaj pes tsawg leeg (chromium, npib tsib xee, titanium, silicon, aluminium, thiab lwm yam) thiab cov qauv sab hauv. Chromium plays lub luag haujlwm tseem ceeb. Chromium muaj cov tshuaj lom neeg ruaj khov, tuaj yeem tsim cov yeeb yaj kiab tsis zoo ntawm cov hlau nto, cais cov hlau los ntawm sab nraud, tiv thaiv cov phaj hlau los ntawm oxidation thiab ua rau cov hlau tsis zoo. Tom qab cov zaj duab xis passivation raug rhuav tshem, qhov corrosion kuj txo.

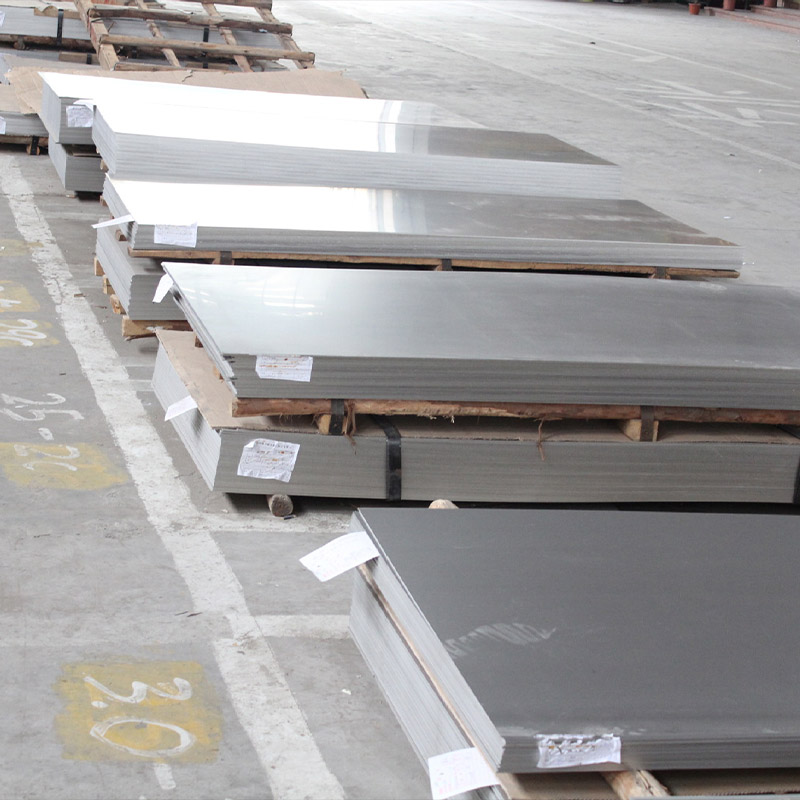

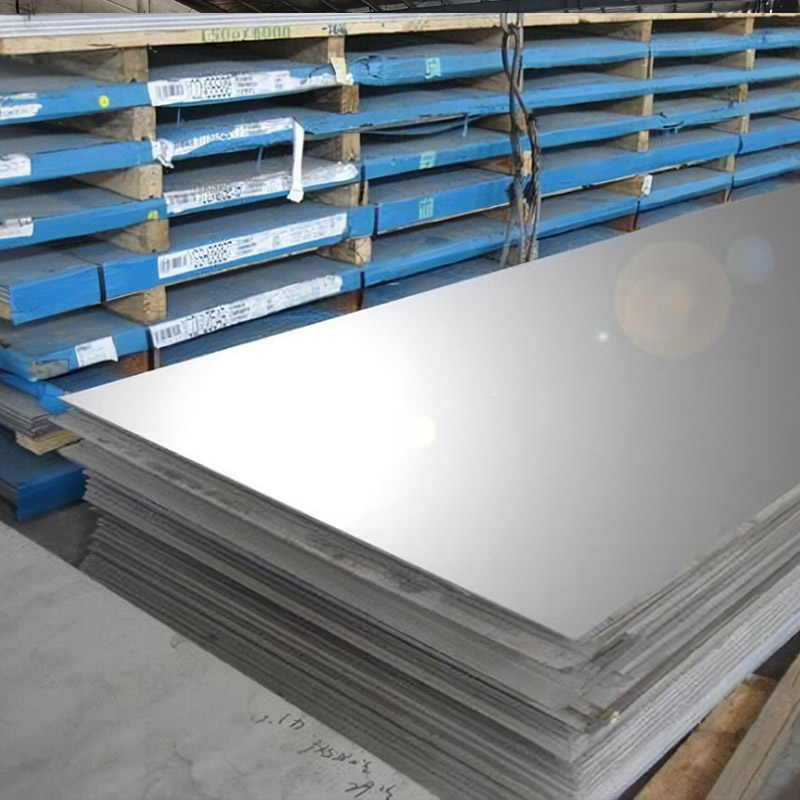

Raws li txoj kev tsim khoom, muaj ob hom kub dov thiab txias dov, nrog rau nyias phaj nrog tuab ntawm 0.5-4 hli thiab tuab phaj nrog tuab ntawm 4.5-35 hli.

Raws li cov yam ntxwv ntawm cov qib steel, nws tuaj yeem muab faib ua 5 hom: austenite hom, austenite ferrite hom, ferrite hom, martensite hom thiab nag lossis daus hardening hom.

Siab zog stainless hlau phaj nrog zoo heev corrosion kuj, dabtsi yog khoov processability thiab toughness ntawm vuam qhov chaw, raws li zoo raws li stamping processability ntawm vuam qhov chaw thiab nws txoj kev tsim. Tshwj xeeb, stainless hlau phaj muaj Si, Mn, P, s, Al thiab Ni nrog cov ntsiab lus tsim nyog tsawg dua 0.02% C, tsawg dua 0.02% N, ntau dua 11% ntawm Cr thiab tsawg dua 17%, thiab ua tau raws li cov kev cai ntawm 12 ≤ Cr Mo 1.5si ≤ 17, 1 ≤ Ni 30 (cn) 0.5 (Mn Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3mo ≥ 16.0, 0.006 ≤ C n ≤ 0.030 yuav tsum tau rhuab mus rau 850 ~ 1250 ℃, thiab tom qab ntawd kev kho cua sov yuav tsum tau nqa tawm ntawm qhov txias ntawm ntau tshaj 1 ℃ / s. Nyob rau hauv txoj kev no, nws tuaj yeem dhau los ua lub siab muaj zog stainless hlau phaj nrog cov ntsiab lus martensite ntau dua 12% los ntawm ntim, siab zog ntawm ntau tshaj 730mpa, corrosion kuj thiab dabtsi yog khoov processability, thiab zoo heev toughness ntawm vuam kub cuam tshuam cheeb tsam. Qhov kev ua tau zoo ntawm cov khoom siv welded tuaj yeem txhim kho tau zoo los ntawm kev rov siv dua Mo, B, thiab lwm yam.